Do it yourself plank production?

When we first got our 039

Stihl chainsaw

we also got a ripping chain with a special adjustable guide that

connects to the chainsaw body. The guide helps to make even cuts when

you want to make planks from a tree.

I think we cut a total of 15

planks from a pine tree that were each about 2 feet long. They worked

good for our foot bridge, but the process was not easy.

We decided making our own

planks was a bit too complex for our skill level, but if you've got the

time and a remote location that makes delivery a challenge then maybe a

chainsaw mill is an option worth considering.

Want more in-depth information? Browse through our books.

Or explore more posts by date or by subject.

About us: Anna Hess and Mark Hamilton spent over a decade living self-sufficiently in the mountains of Virginia before moving north to start over from scratch in the foothills of Ohio. They've experimented with permaculture, no-till gardening, trailersteading, home-based microbusinesses and much more, writing about their adventures in both blogs and books.

Want to be notified when new comments are posted on this page? Click on the RSS button after you add a comment to subscribe to the comment feed, or simply check the box beside "email replies to me" while writing your comment.

I have an (I think it is called "Canadian sawmill") attachment for my saw. You tack a 2x4 along the top of a log, and the guide fits over it. Then you move the saw down the log to make a plank. It works OK, but my saw was pretty dull (not anymore- Thanks Mark!) I managed to make quite a few 1" x various" x 6' planks. And I am left with a good sized beam of heartwood.

Well Phil, in my case, a 2x6x12' costs about 1300 yen- about 15USD. I can cut two of them (and a few smaller slabs as well) without filling my chainsaw gas tank- about 300ml. One liter of gas is 140 yen... so it costs less than 70 yen per board (about a dollar). Of course, it takes an hour of my time. I think it is pretty cost effective, if you have free raw material and time to spare to start with.

Eric-The addition of a 2x4 as a guide sounds like a good improvement. I remember having some trouble with ours as the guide pushed up against the round part of the log for the first cut.

Phil-I agree. When you crunch the numbers it would most likely work out better to buy lumber at the store, and will surely last longer if you get treated wood that was cured by someone who knows how to do it right.

Roland-I've seen those man-portable band saws and agree that it would be a far better choice for lumber production and less waste. I heard of a guy who bought one for around 5000 dollars, used it for a project and then turned around and sold it for the exact same amount.

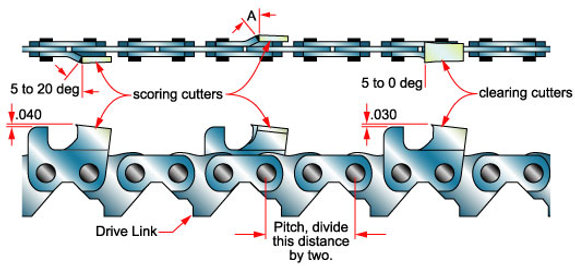

It had never occurred to me but the ripping chain illustration and idea of using rip fences to guide a chainsaw has inspired me to consider the chainsaw for deep dado cuts in rough joinery of large timbers.

With an elaborate fence you could even insert a chainsaw end-first into a block of wood to create a mortise 24" deep . . . wow!

] j [

@Jeremiah: You mean like a chain mortiser? I wonder how much accuracy you'd get from a common chainsaw? The chains for a mortiser seem to be constructed quite differently from those of a chainsaw.

Besides, if you can use a feather tenon (tenons with rounded edges), which are easy to make with a correct router bit on a router table, you can use a simple router to make the mortises. With a good guide and a sharp milling cutter, I don't think you can beat the accuracy of a router. With our CNC milling machine at work we've cut jigs from plywood that fit together like a puzzle without discernable play.

Matthias Wandel of woodgears.ca has done some interesting strength tests of different types of woodjoints.

In wood as in other materials, bigger joints aren't necessarily stronger. What matters most is where stress concentrations occur. Because that is where the joint will fail. Wood is an anisotropic material (it is much easier to split along the grain than across it) so the orientation of the grains matter.